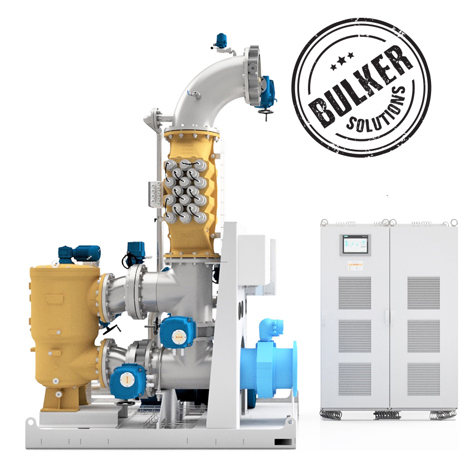

Ballast Water Treatment Systems | CompactClean

DESMI’s CompactClean Ballast Water Management & Treatment Systems offer high quality, compliant performance anywhere in the world – even in extremely dirty and challenging water conditions. They are approved for operation in waters regulated by the International Maritime Organization (IMO) and by the United States Coast Guard (USCG).

CompactClean has no salinity or temperature limitations and fits in any vessel type due to the various sizes ranging from down to 35 m³/h and up to 2500 m³/h. The Ballast Water Management Systems operates in the exact same way both inside and outside US Territory at record-breaking low UV transmission values!

We offer three system variants:

WHY COMPACTCLEAN IS YOUR ANSWER

- The smallest footprint in the industry

- Only system in the world with integrated stripping solution

- Automatic flow control and lamp dimming

- Worldwide service network

- Fully automated operation

- 2 hours’ holding time on USCG TA Certificate

- IMO type approval according to the new BWMS code from IMO

- Graphic HMI touchscreen interface

- Automatic generation of PDF reports to authorities

- Short delivery time

- Easy maintenance

- No salinity or temperature limitations

- Down to UV Transmission of just 35% in IMO waters and 40% in USCG territory

- 100% chemical free treatment

THREE OVERALL CONFIGURATION TYPES

LOOSE COMPONENTS

SKID MOUNTED

DECKHOUSE

Frequently asked questions

Which ballast water system does my ship need?

It is important to look at your vessels trading pattern, some systems has been optimized for certain types of operation. The CompactClean system comes in different variants, namely;

- CompactClean – for worldwide operation and simple operation, one treatment mode for the entire world.

- CompactClean OptIMO – optimized for operation mainly in IMO waters, dual mode software with specific treatment mode for IMO and USCG waters.

- CompactClean Bulker – specifically designed for the operation pattern of a bulker vessel. Can treat double the amount of water during discharge.

Do you provide Engineering services?

DESMI Ocean Guards has its own Engineering Department which can perform all necessary parts of Engineering to ensure the most optimal installation of a CompactClean system. The Engineering package can contain everything from 3D scanning till the final Engineering drawings for Class. Review can also be performed of 3rd party engineering.

Do you provide installation (turnkey)?

Normally your preferred shipyard will perform the installation based on the Engineering. However, we have partners which can undertake the a turnkey delivery with DESMI Ocean Guard as subcontractors.

Are there any special requirements with regards to installation (water cooling or compressed air)?

The CompactClean system is very simple to install. It more or less only requires a power connections. All valves in the system are electrical actuates. This eliminates the hassle of pneumatic valves. Furthermore, the main electrical cabinet is air-cooled, so no need to install additional water cooling.

How do I navigate the ballast water management convention?

On 28 October 2020, most of the world’s ports will close to new ballast water treatment systems installed on or after that date without meeting IMO BWMS CODE requirements. - To ensure compliance and operability of your vessel you should choose a Ballast Water Management System having the IMO BWMS Code type approval.

What are the ballast water treatment regulations?

A known challenge for UV-based BWM systems is the different regulations, requirements, and efficacy testing methods adopted by the two regulatory bodies; USCG and the IMO.

The USCG evaluates BWM system performance using a test which measures the number of living organisms after treatment (FDA/CMFDA method). On the other hand, the IMO evaluates UV-based BWM systems by determining whether the treated organisms are viable or non-viable, i.e. are they capable of reproducing.

Learn more about the BWTS regulations and other relevant topic in our FAQ section

MAIN PANEL:

The CompactClean BWMS is controlled via the HMI panel. The main panel can be placed 100 meter away from the system

START-UP:

Before igniting the UV lamps, the system makes sure the UV lamps are covered with water. If the UV lamps are not covered with water - The system automatically takes in fresh water. The sensor registers that the unit is filled with water and ignites the UV lamps

WARM-UP:

The system stops the fresh water filling and switches to recirculation. The DESMI Modular S pump recirculates the water through the UV-unit.

START BALLAST OPERATION

When the UV Lamps reach the right temperature, the system is ready for ballast operation. The ballast water is directed to the filter and then the UV unit before being pumped to the ballast tank

FILTER BACKFLUSH

During ballast operation the filter accumulates sediments and large organisms. When a certain differential pressure is reached, the filter will automatically clean itself. In this case, the DESMI modular S pump pumps the backflush water from the filter to the sea.

RECIRCULATION

After all operations involving the UV-lamps, the system automatically switches to recirculation for 2 minutes in order to cool down the UV-lamps

DE-BALLAST OPERATION

The de-ballast procedure is the same as the ballast procedure but with the filter by-passed

STRIPPING AND CLEANING IN PLACE

After the deballasting operation the DESMI modular S pump can be used as a stripping pump during stripping operations. Once stripping is completed, the CompactClean system can perform cleaning in place. To do so please add citric acid tot the system and start the cleaning in place operation mode. The citric acid will be recirculated through the system cleaning the UV-unit.